Start Deploying Your Smart System Today!

Conventional Systems are obsolete. Get in with the future.

In addition to checking on whether a camera is working effectively the system can also tell if pieces of equipment that the cameras are watching are operating correctly and even predict when maintenance is due.

Equipment maintenance and the maintenance of facilities is critically important for an organization. Equipment failure through poor maintenance can result in a huge unnecessary cost and generate safety concerns. And maintenance itself can be an expensive labour intensive exercise.

With its multi-sensory AI capabilities iOmniscient offers a portfolio of capabilities that can detect and even predict equipment failure and greatly increase the productivity of maintenance staff by up to 100%.

Maintaining CCTV networks

If you run a large CCTV network the chances are that just when there is an incident in your facility the mission critical cameras that you are relying on are not working. The key challenge is to know which ones are not operating correctly and why. Studies have shown that in any large network of cameras around 20% are not operational at any time leaving the organization partially blind.

CCTV cameras may not operate effectively because they could have moved due to external vibrations; they could have been sabotaged by a miscreant or they could just not be working because a connecting wire was damaged. Or they could be working but cannot see clearly because of fog or snow or because a spider has spun its web over the lens.

If the camera is not working or if it has been sabotaged or it just cannot see clearly for any reason the system will raise a warning and issue a maintenance ticket for the team to address the problem immediately or as per a maintenance schedule

The warnings can be grouped by location so as to optimize the route to be taken by the maintenance person. The improved scheduling has been demonstrated to result in an almost instantaneous 40% improvement in productivity for the maintenance team.

iOmniscient’s IQ-HealthCheck can automate the above steps keeping an eye on every camera to ensure they are all operating effectively 24×7.

Maintaining Equipment that the cameras can see

In addition to checking on whether a camera is working effectively the system can also tell if pieces of equipment that the cameras are watching are operating correctly and even predict when maintenance is due.

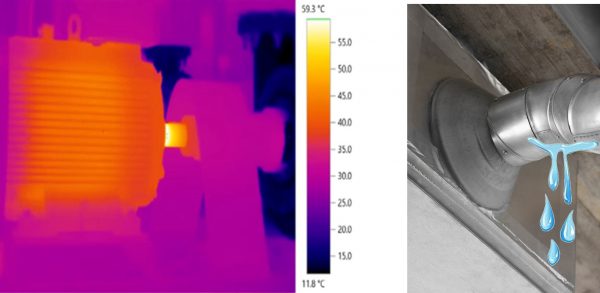

In the advanced version, the system can also understand the maintenance status of many of the objects that it is looking at. For instance, it can tell if a motor is over heating or if a pipe is leaking.

Predictive Maintenance achieves the highest ROI

The system can also be used for preventive maintenance – anticipating potential problems.

For instance, it can tell if objects like screws or coins fall onto an escalator step. It can then autonomously stop the escalator while sending a message to a local staff member to clear the step before the items damage the mechanism of the escalator. Organizations using this particular option have been able to achieve a pay back on their investment in just 8 weeks through eliminating the high cost of escalator repair.

Another Preventive Maintenance offering from iOmniscient involved workers who were required to physically read equipment meters in the basements of various hospitals and other similar buildings. Based on the meter readings they had to determine whether the equipment was working effectively.

The challenge was that the maintenance workers made many errors in recording the data from the meters. Further as they did not have historic data readily available their ability to predict problems was very limited.

Having both analog and digital meters read automatically using fixed CCTV cameras and where needed using iOmniscient’s IQ-Mobile App (available for both IOS and Android devices), the system had an accurate reading of the meters.

With immediate access to historic data for the same meters the system could pre-emptively advise if some equipment was on the verge of malfunctioning.

In restaurants and places where food is stored the system will detect the presence of rodents that constitute a serious health risk.

In every case a preventive system greatly reduces the ultimate cost of maintenance.

Maintenance Using Combined Sound and Smell Analytics

iOmniscient’s portfolio of capabilities goes beyond video to Sound to Smell.

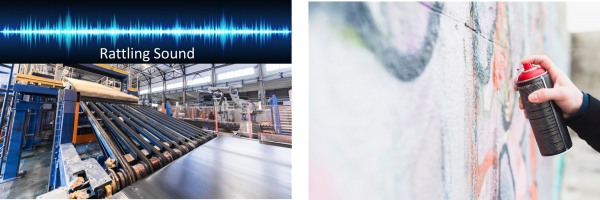

Along with visual AI, the system can often hear the rattling sound from equipment and know that there is something that is not operating correctly.

iOmniscient’s e-Nose can be used to pick up complex abnormal chemicals including toxic leaks from underground tunnels before inspectors are sent down.

They have been used to detect spray paint to provide an early warning that someone was painting graffiti in an area which may not have been covered by cameras. It can pick up gas leaks and other smells that indicate that something is not working correctly in a location.

And all this at Zero incremental cost

iOmniscient’s advanced AI capability goes beyond Deep Learning. It is very computing light and no GPUs are required.

Further with its smart compression capability all systems can reduce their storage and network bandwidth requirement by around 90%.

iOmniscient designs its use cases such that the ROI is very tangible and the overall cost of the system is usually below that of a recording system.

Start Deploying Your Smart System Today!

Conventional Systems are obsolete. Get in with the future.